Repair or Replace? A Decision Framework for IT Managers

If you’re managing IT hardware, you’ve faced the question: “Should we fix this, or just replace it?”

It seems simple. But in reality, it’s one of the trickiest decisions IT teams make. Choosing wrong can mean blowing the budget, risking downtime, or replacing gear that still has years of value left.

Most teams don’t have a reliable system for making this call. Too often, it’s based on gut instinct or vendor pressure to buy something new.

Here’s a framework that helps you answer the question with clarity, confidence, and strategy. You’ll save money, extend the life of your equipment, and stay aligned with your sustainability goals.

Why This Decision Matters More Than Ever

Making the right call on repair vs. replace is about solving for the bigger picture. Budgets, supply chains, and sustainability are all in play.

The pressure is real:

- Budgets are tighter than ever. You’re being asked to do more with less, and that means squeezing value out of every asset.

- New gear isn’t always easy to get. Lead times for replacement equipment can stretch for months. That delay can hurt operations or force quick decisions you’ll regret later.

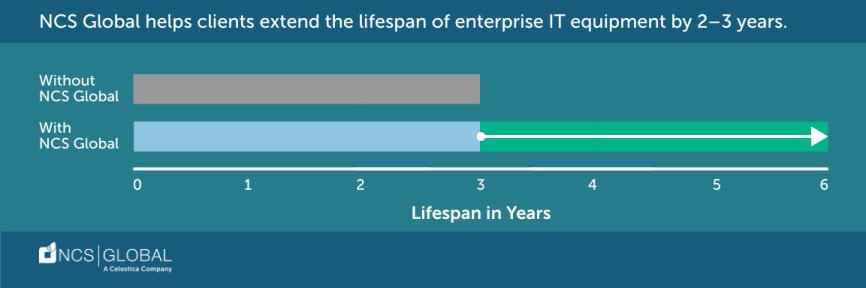

- Sustainability is now a priority. Teams are being asked to reduce e-waste and carbon output. Keeping good hardware in service longer is one of the simplest (and smartest) ways to hit ESG goals.

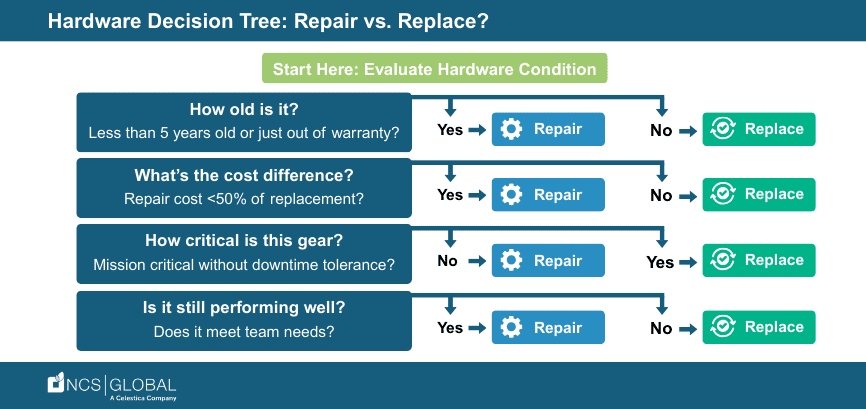

A Simple Framework: 4 Things to Check First

Here’s a straightforward way to think through your options every time.

1. How old is it?

If the hardware just moved out of warranty and is still under five years old, it probably still has life left. But once you’re at the 7+ year mark, parts get harder to find, and the risk of failure starts rising.

2. What’s the cost difference?

Look beyond the sticker price. If the repair will cost half or less of what a replacement would, it’s likely worth doing. But if repairs creep over that 60% mark, replacing might save you more in the long run.

3. How critical is this gear?

Some assets can afford downtime. Others can’t. If it’s mission-critical equipment, and a repair would leave you vulnerable, replacement might be the safer call.

4. Is it still performing well?

A successful repair only helps if the gear can still meet the needs of your team. If slow performance or outdated specs are causing problems, a repair won’t fix that.

Real-World Examples: What to Do and When

Still not sure? Here are a few quick-hit scenarios IT managers see all the time, and how they usually play out.

How NCS Global Makes the Decision Easier

You don’t have to make these calls alone or blindly.

At NCS Global, we help IT teams across industries figure out the smartest next move for every piece of equipment. Here’s what that looks like:

1. Diagnostics for Out-of-Warranty Equipment

If the OEM isn’t supporting the gear anymore, we still are. We offer diagnostic services and parts sourcing to help you understand what’s fixable, what’s not, and what it’ll cost before you commit.

2. Full-Service Reverse Logistics

Need help with the physical side of things? We’ll pick up, repair, and return your equipment, or redeploy it elsewhere in your environment. Our customer portal keeps everything tracked, so you’re never left wondering where anything is.

3. Sustainability Reports

If your team is focused on ESG reporting, we’ve got you. Every reuse or repair we do includes environmental impact data so you can measure the value you’re creating beyond the balance sheet.

Make Every Asset Count

If you’ve ever replaced a device only to realize later it could have been repaired, you’re not alone. With a consistent, data-driven process and the right support, you can make decisions that are smarter for your team, your budget, and the planet.

Need help figuring out whether to repair or replace? Let NCS Global take the guesswork out of it. We’ll help you stretch every dollar and get more life from the gear you already own.